Designed to simulate and solve engineering problems of molds in plastic injection molding process. This will reduce mold testing time, reduce costs, increase productivity and increase confidence in the mold design process. It also evaluates the design options. The new model will be used to simulate every detail during the injection molding process. The workpiece is the highest quality and most efficient production process.

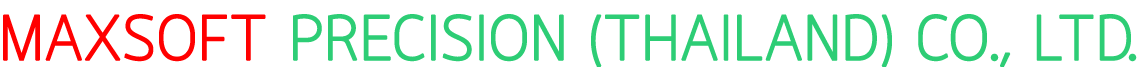

Inspected and controlled every step by a team of expert engineers. You can be assured of the quality of the molds we make.

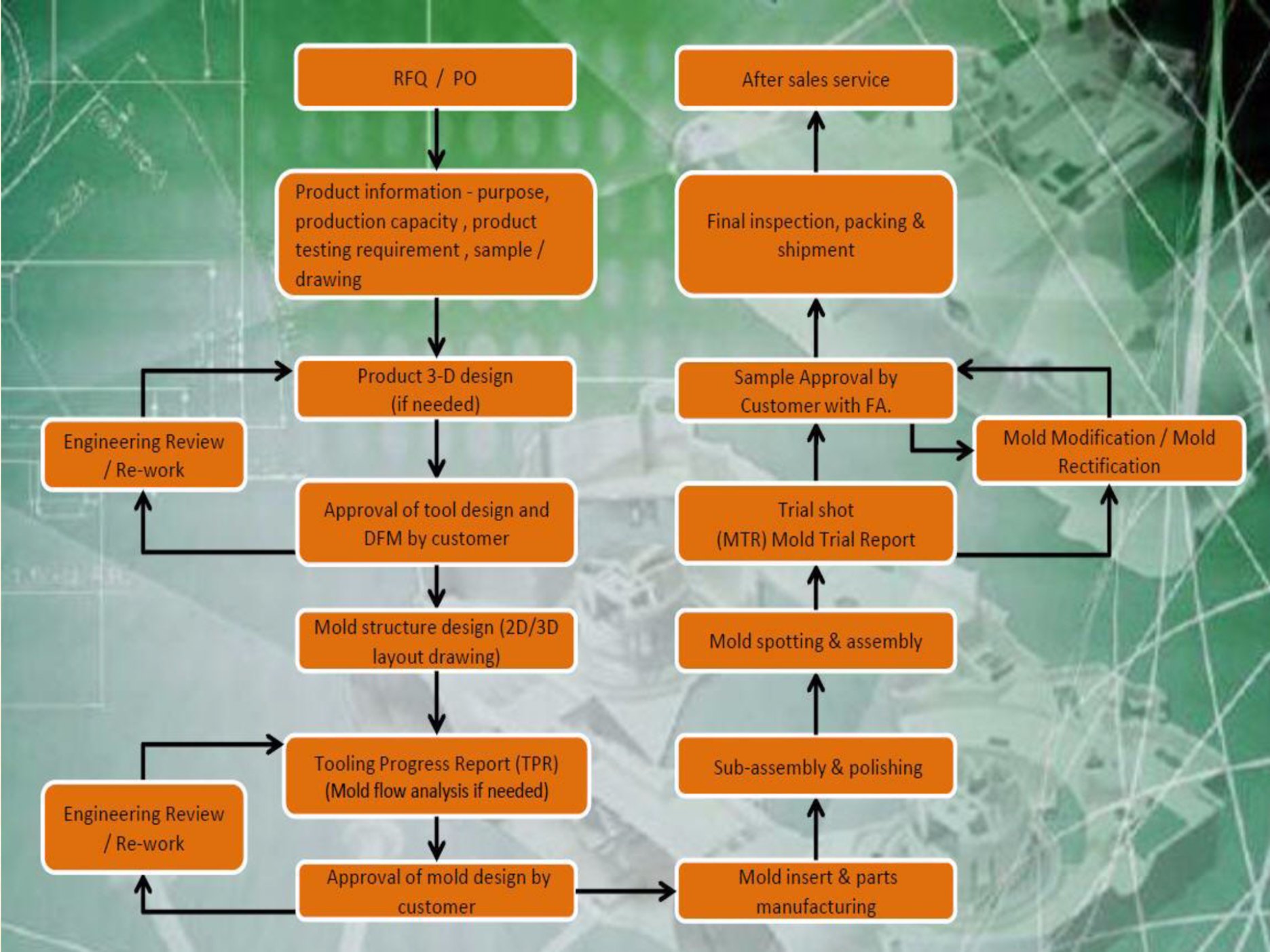

Tool Fabrication

Molding Future Plan.

- More than 20 high precision machines.

- Press ranging from 30˜350 Ton.

- Transplant with Equivalent Customer Capability.

- Contract Manufacturing Future Plan.

- ESD Ready.

- Customized Assembly Lines.

- Value Added Processes.

OUR CAPABILITIES

Specialize in fabricating Precision Engineering Parts.

- Tight tolerance up to 20 micron part level.

- Thin Wall molding up to 0.1mm & High Complexity.

- Supported by EROWA system & Shrink-fit chuck arbor.

- Ultrasonic Polishing.

Gear.

- Various Standards– AGMA, JIS, JGMA, DIN, ISO & etc.

- Up to AGMA 9 or JGMA 3 accuracy.

Connectors.

- Electronic applications.

- House hold appliance.

- Automotive.

Insert & Out-sert Mold.

- Over-molding with tight tolerances.